mep solutions

VOLUME CONTROL DAMPERS

Precision, Durability, and Efficiency for HVAC Systems

Our premium Volume Control Dampers offer precise airflow control, durable construction, and customizable options to suit your HVAC needs. They help optimize system efficiency and reduce energy waste, ensuring seamless integration into any project Volume Control Dampers: its importance in HVAC systems, and typical applications. Key Features: List of key features, such as durability, precision control, and customization options.

Ordering information

How to Order: Steps for ordering, including how to specify sizes, materials, and options. Lead Times: Typical manufacturing times. Contact Information: Sales and support contact details.

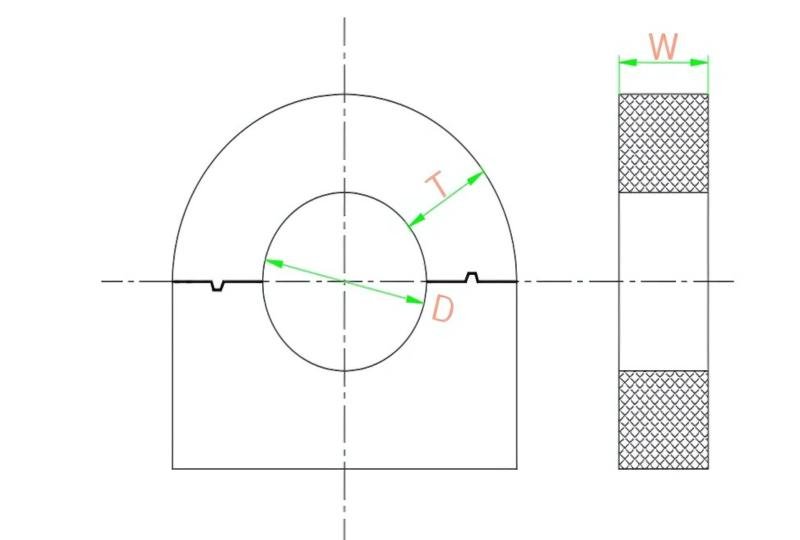

Product Drawings & Diagrams

Technical Drawings: Provide dimension drawings for standard damper models. Cross-Section Views: Illustrate internal components and assembly. Wiring Diagrams: For electric and pneumatic actuators.

Warranty & supports

Warranty Information: Details on products warranty coverage. Support Services: Available technical support, including installation, troubleshooting, and maintenance.

Product specification

1. Material Specification

- Galvanized Steel : composition, corrosion resistance and specification

- Stainless Steel : Grade available, ideal environments and advantages

2. Frame and Blade Thickness

- Frame Thickness :

Options : 16-gauge(1.2mm), 18-gauge(1.0mm), 20-gauge(0.8mm). - Applications : Different gauges for varying airflow and pressure needs

3. Finish Options

- Painted Finish:

- Color Options : Available colors.

- Applications : Where aesthetics and protection are essential.

- Galvanized Finish :

- Description : Galvanized Sheet finish without additional coatings.

- Mounting Options: Detailed instructions for flange-mounted and slip-in installation.

- Maintenance Tips: Routine maintenance and inspection recommendations.

- Troubleshooting: Common issues and solutions.

- Dampers without flanges available as option for duct insertion purpose

4. Blade Types

- Opposed Blade:

- Description: Blades move in opposite directions for finer control.

- Applications: Best for mixing or modulating airflow.

- Advantages: Improved airflow distribution and control

5. Electric Actuators

- Types : Motorized, integrated with BMS.

- Benefits : Automation, precision, Remote control.

- Actuators of client’s choice will be supplied separately.

- Dampers will be provided with extended spindle to fix actuator on-site

6.Sealing Options

- Blade Seals :

- Materials : Silicone, EPDM.

- Purpose : Minimize air leakage.

Material Specification

- Galvanized Steel : composition, corrosion resistance and specification,

- Stainless Steel : Grade available, ideal environments and advantages.

Frame and Blade Thickness

- Frame Thickness :

Options : 16-gauge(1.2mm), 18-gauge(1.0mm), 20-gauge(0.8mm). - Applications : Different gauges for varying airflow and pressure needs

Finish Options

- Painted Finish:

- Color Options : Available colors.

- Applications : Where aesthetics and protection are essential.

- Galvanized Finish :

- Description : Galvanized Sheet finish without additional coatings.

- Mounting Options: Detailed instructions for flange-mounted and slip-in installation.

- Maintenance Tips: Routine maintenance and inspection recommendations.

- Troubleshooting: Common issues and solutions.

- Dampers without flanges available as option for duct insertion purpose

Blade Types

- Opposed Blade:

- Description: Blades move in opposite directions for finer control.

- Applications: Best for mixing or modulating airflow.

- Advantages: Improved airflow distribution and control

Electric Actuators

- Types : Motorized, integrated with BMS.

- Benefits : Automation, precision, Remote control.

- Actuators of client’s choice will be supplied separately.

- Dampers will be provided with extended spindle to fix actuator on-site

Sealing Options

- Blade Seals :

- Materials : Silicone, EPDM.

- Purpose : Minimize air leakage.

Core Feature

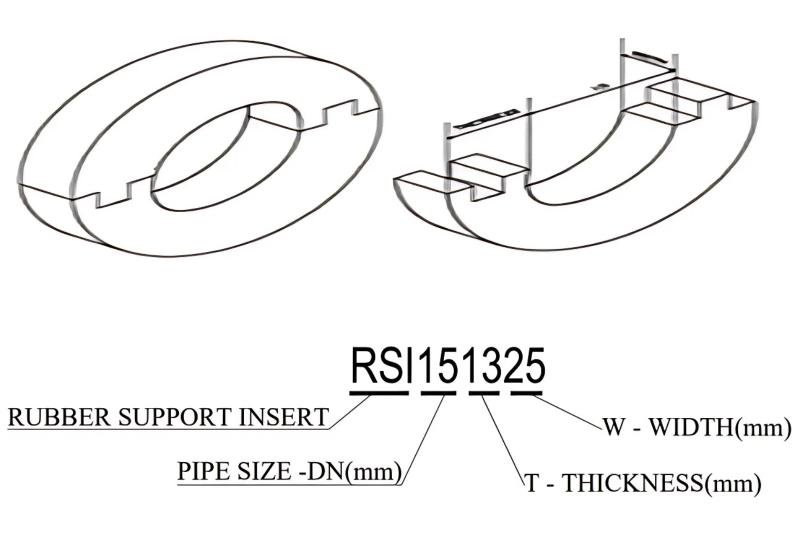

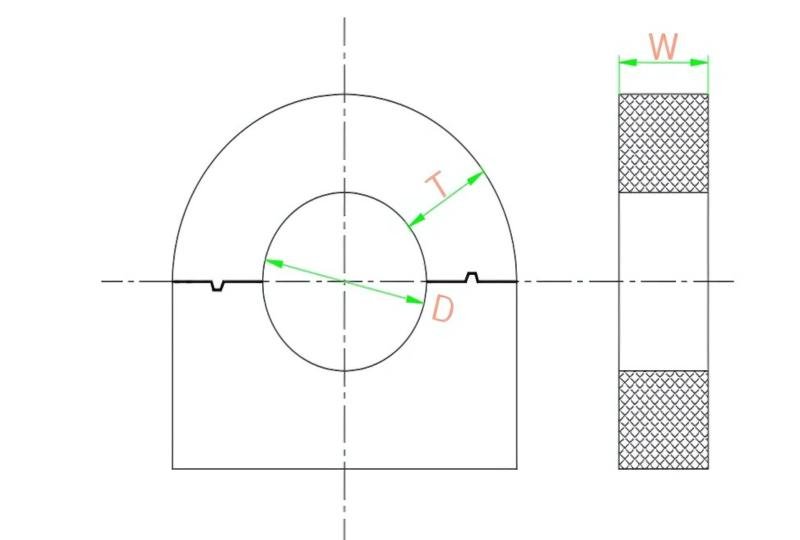

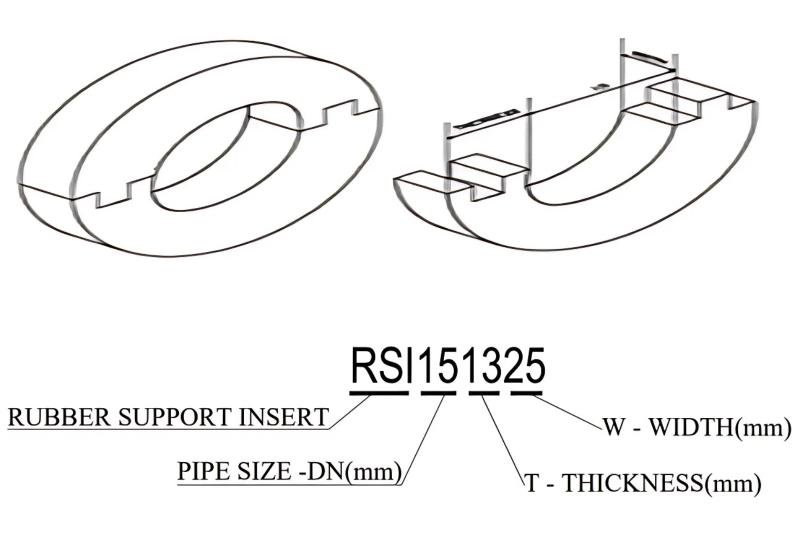

RUBBER SUPPORT INSERT FOR PVC PIPES

About

Durable, Precise, and High-Performance Solutions

A practical and effective way to prevent crushing of insulation at pipe support locations of Chilled water, Condenser water, and domestic hot/cold water installations.

Features & Benefits:

- Used at the supporting points of insulated pipes to prevent crushing of insulation.

- Inherently superior to wood. Very high load bearing capacity Dimensional accuracy, since each piece is machine molded.

- Excellent resistance to deterioration/distortion.

- Density max:1200 kg/m3

- Thermal conductivity: 0.16 w/m

- Temperature resistance from -20°C to +100°

- RSI is Eco-friendly product. Eliminates the need for felling trees just to make pipe support rings

- D Type also available

Standard Width:

- 1 /2″ to 2″ : 25mm

- 2 1/2″ to 5″ : 38mm

- 6″ and above : 50mm

- Customized widths also available

Pip pipes

TABLE OF RSI SIZE FOR THE SELECTION OF PVC PIPES

Hanging Materials

TABLE OF RSI OUTER DIAMETER FOR THE HANGING MATERIAL SELECTION

Core Feature

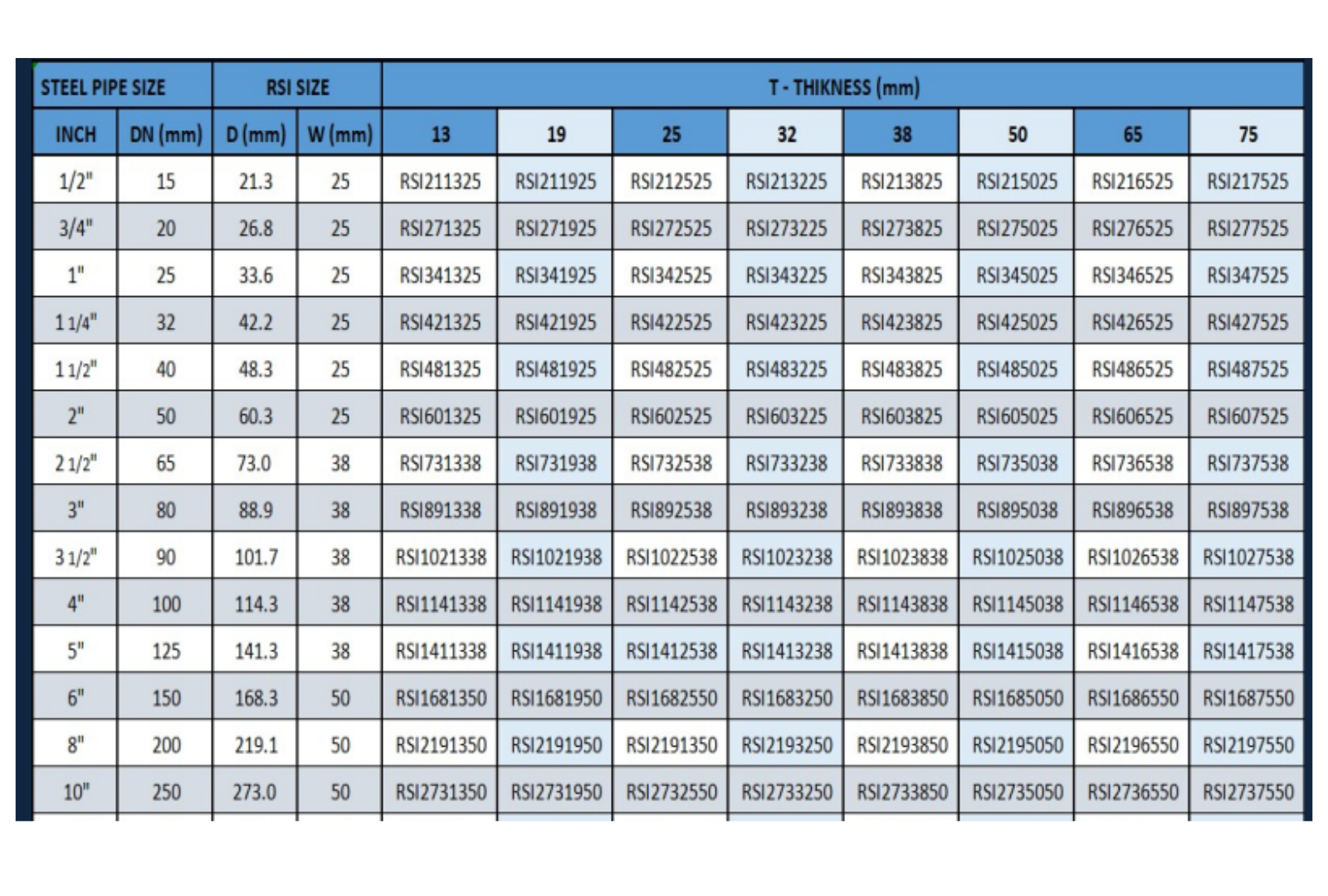

RUBBER SUPPORT INSERT FOR STEEL PIPES

About

Durable, Precise, and High-Performance Solutions

A practical and effective way to prevent crushing of insulation at pipe support locations of Chilled water, Condenser water, and domestic hot/cold water installations.

Features & Benefits:

- Used at the supporting points of insulated pipes to prevent crushing of insulation.

- Inherently superior to wood. Very high load bearing capacity Dimensional accuracy, since each piece is machine molded.

- Excellent resistance to deterioration/distortion.

- Density max : 1200 kg/m3

- Thermal conductivity: 0.16 w/m

- Temperature resistance from -20°C to +100°

- RSI is Eco – friendly product. Eliminates the need for felling trees just to make pipe support rings

- D Type also available

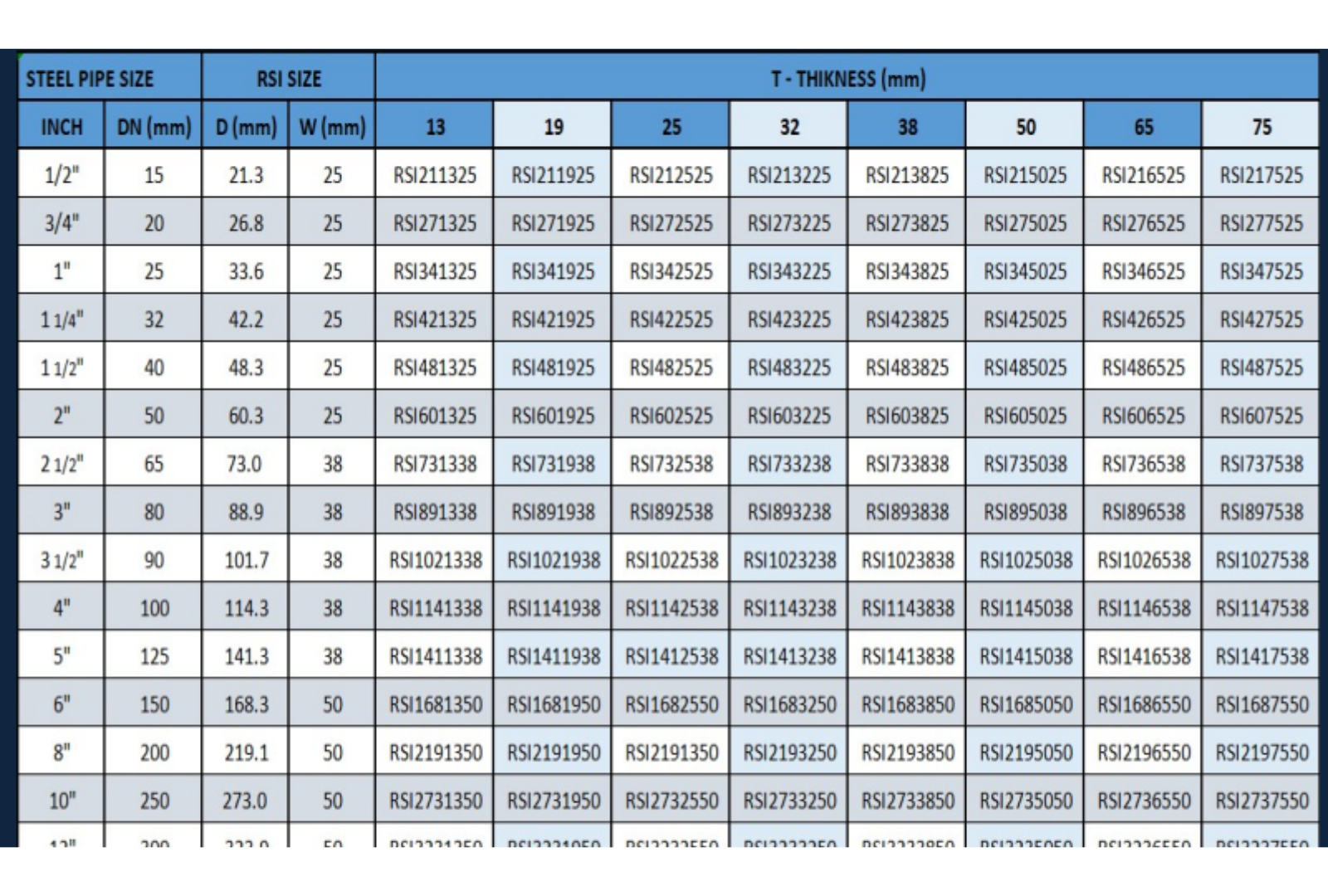

Standard Width:

- 1 /2″ to 2″ : 25mm

- 2 1/2″ to 5″ : 38mm

- 6″ and above : 50mm

- Customized widths also available

STEEL PIPES

TABLE OF RSI SIZE FOR THE SELECTION OF STEEL PIPES

Hanging Materials

TABLE OF RSI OUTER DIAMETER FOR THE HANGING MATERIAL SELECTION

Company

Strategy

MATERIAL SUPPLIED BY MEP SOLUTIONS

NBR INSULATIONS (GULF -O -FLEX)

RUBBER SUPPORT INSERT (RSI)

VFD (YASKAWA)

DUCT SHEET / ACCESSORIES

MOTORIZED VCD

DUCT FABRICATION

VOLUME CONTROL DAMPER

HANGING MATERIALS

GI NUT & BOLT

LP/ CO2/ RH SENSORS

FLEXIBLE DUCTS